WORKING SERVICES

Welcome to Sunsavor (Pty) Ltd

Our objective is to meet our customer needs consistantly with quality, competitively priced products

Johan du Plessis the owner of Sunsavor is ready to assist

Santos Port container handling facility in Brazil is one point from where soybeans are imported.

Sunsavor (Pty) Ltd

Well positioned to meet your Needs

Sunsavor through it’s collaborators offers quality products to the food industry. A variety of agricultural commodities such as soya, sugar, rice , pulses and spices are milled in a facility with a certified food safety management system. We offer both standard products but also operate in a sub-contractor role to process your commodities, according to your bespoke specifications if required.

procurement of Raw Materials

Quality agricultural inputs are sourced both locally and imported from other countries. Final products (Icing sugar being the exception) are single ingredient naturally processed commodities. The quality of the final product is largely dependant on the quality of the input – therefore all inputs are procured from vetted suppliers, according to specifications. Particular attention is paid to residual chemical and microbiological testing for purposes of food safety.

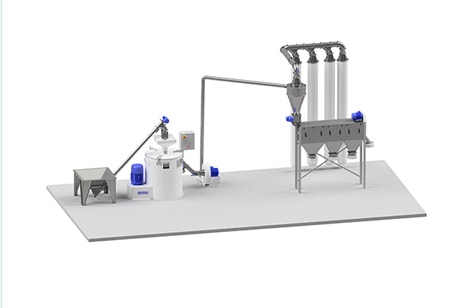

how do we do it

- The raw material is fed into a size reduction unit first . The type of unit depending on the properties of the raw material. Thereafter it is

- conveyed pneumatically to a sieving element and

- then screened for size through appropriately sized mesh

Size Reduction Units - impact and Grinding Mills used in the mill

Alpine Contra-plex Pin Mill

The wide bodied Alpine Contra-plex pin mill is an impact mill well suited to mill a range of commodities into a fine flour. The wide body prevents product from “caking up” in the machine (especially commodities with a high fat content)

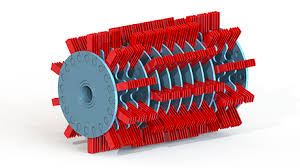

Hammer Mill

In the Pin Mill above multiple pins impact on the food particles to reduce size. The hammermill is also an impact mill but in this case a large number of “hammers ” mounted on a drum rotate at high speed impacting on food particles, forcing them through a screen resulting in reduced particle size

Stone Mill

Stones are powerfull milling elements bringing about size reduction through a combination of pressure and shearing forces. Although running relatively slow the huge contact surface involved brings about particle size reduction with relative small increase in product temperature

steel Rollers

Steel Rollers work in pairs. One roller runs slower than the other, serving a holding function for the faster roller. Grain particles are “forced” into the gap, compressed and the faster roller then shears off parts of the particles to reduce size.